The number of users of 3d printing are skyrocketing. And, according to the 3D Printing Market Forecast from 2014-2026, published earlier this year shows that this trend is expected to grow by 21% in 2022 and achieve a 24% compound annual growth rate until 2026.

On this occasion, in today’s article, we’ve decided to talk about the different types of 3D printing, and in the second part of our blog, we will uncover some of their benefits and the main areas that use this technology.

This type of printing consists of manufacturing parts from a 3D model, designed in CAD software (computer-aided design), through a process of deposition (passage from solid to semi-liquid state) of layers of material and their subsequent consolidation. 3D printing can be carried out using different printing methods – let’s learn more about them.

Types of 3d Printing

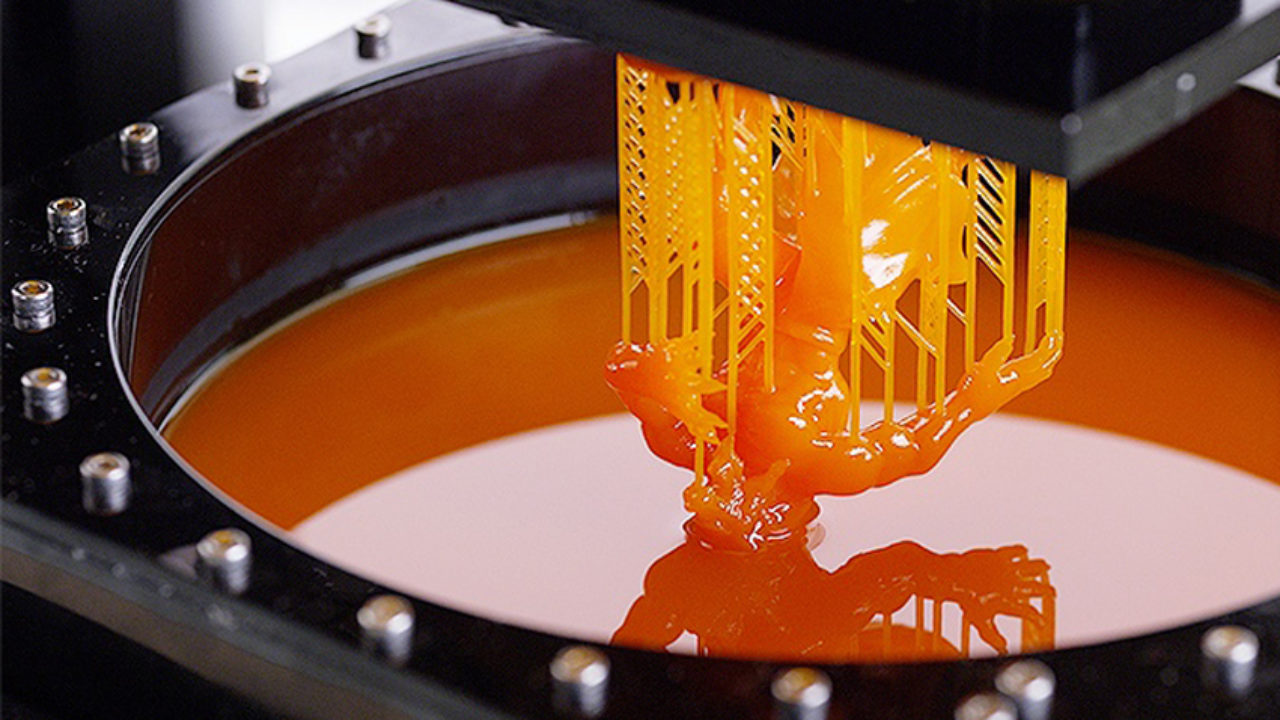

Stereolithography 3D Printers (SLA)

It consists in the application of ultraviolet light on a resin in liquid state which is in a cubic container sensitive to the ultraviolet light.

The ultraviolet light solidifies the resin layer by layer. The base that supports the structure descends so that the light returns to exert its action on the new bathroom, until the object reaches the desired shape, then the base that supports the structure rises with the desired figure (this is cleaned with isopropyl alcohol).

With this method, very good quality parts are obtained, although, to remove a drawback, a certain amount of material is wasted depending on the support that must be manufactured.

Selective Laser Sintering (SLS) 3D Printers

This technology involves colliding the laser with the material used to print the 3D objects.

Although it has some similarities with SLA technology, it allows the use of different types of powder materials (ceramic, glass, nylon, polystyrene, etc.). The laser hits the powder, melts the material and solidifies it. Any material that is not used is stored in the same place where the printing began, so nothing is wasted.

Injection 3D Printers

This is the closest 3D printing system to a regular inkjet printer, but instead of injecting drops of ink onto paper, they inject layers of liquid photopolymer that can be cured on the build plate to make the desired part. This process is more industrial.

Fused Deposition Printing (FDM)

This is the most widely used technique in the world of 3D printing, it is a technology that involves depositing a molten polymer (Filament) on a flat base, layer by layer. The material, which is initially in a solid state stored in rollers, melts and is expelled through the nozzle into tiny threads that solidify on contact with the base, which is at a temperature normally above 50 degrees Celsius.

The main advantage is that this technology has made 3D printing available to everyone. The Creality brand series is one of the most commercialized 3D printers in the world, with greater support and spare parts available for users. An example would be the ENDER-3-PRO .

Currently, in this type of 3D printing, a wide variety of materials are used, among which ABS and PLA polymers (PLA1.75MM-BLACK) predominate.

Types of Fused Deposition Modeling (FDM) 3D printers: Delta, Cartesian, Polar and Hybrid

Cartesian 3D printers

This is the most common type of FDM printer on the market. They are so named because of the Cartesian coordinate system they use. It consists of three orthogonal axes (right angles), the X, Y and Z axes, which are used to determine where and how the print head should move correctly in all three dimensions.

Delta 3D printer

They work with Cartesian coordinates and their main features are the circular print bed combined with the extruder that is attached above with a triangular configuration and with 3 arms that support this figure.

Each of the 3 arms can move up and down, left and right, allowing the print head to move in three dimensions. Therefore, the manufacturing limits of these machines are only defined by the diameter of the base and the height of the arms.

Delta 3D printers were designed to increase the speed of printing.

There you are! Want to learn more about this technology? Come back to check the second part of our article. Until then, tell us in the comments below your thoughts on this way of printing.